Cobra

King Tour

Why we like it

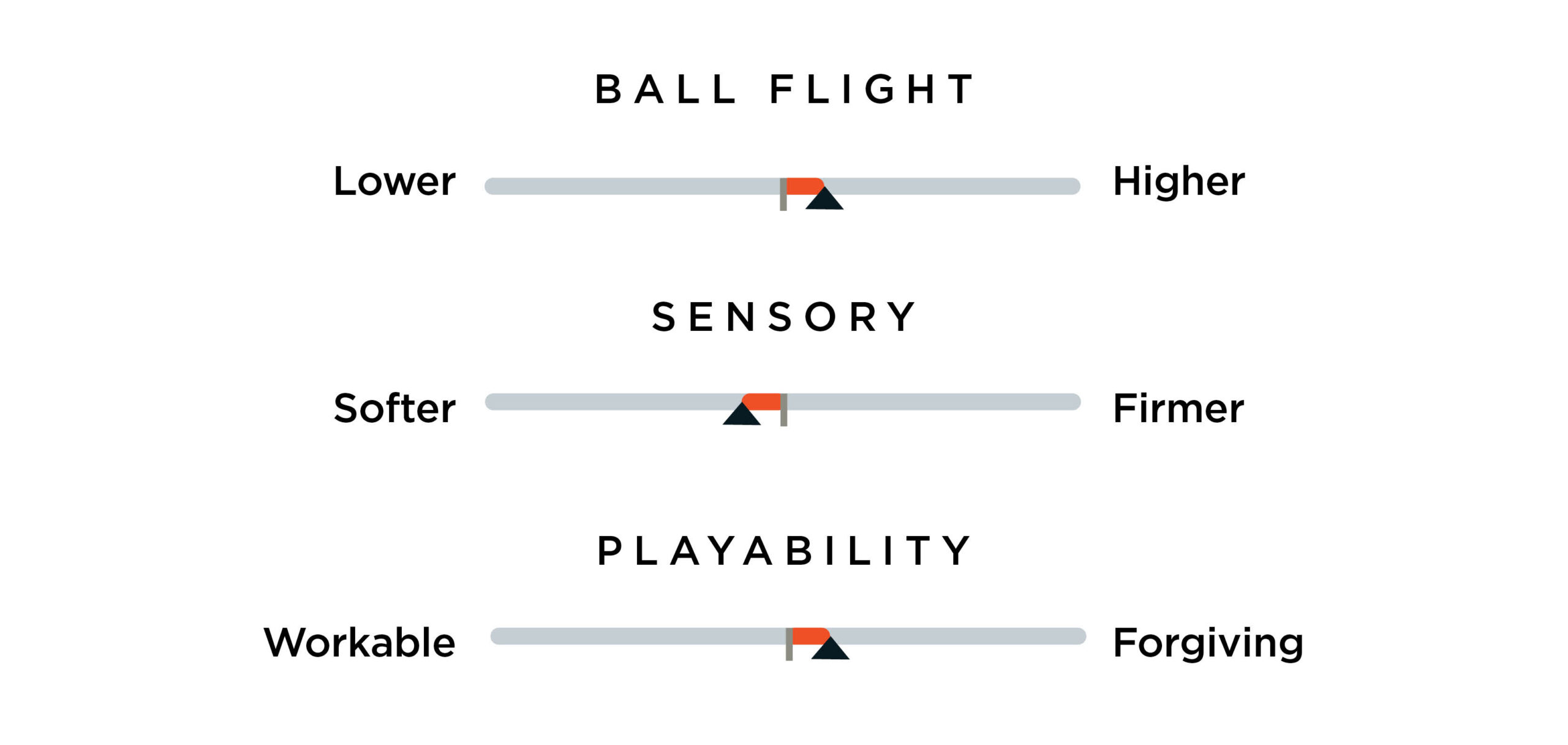

Most traditional irons use a two or three-step forging process, but these irons feature a five-step process that more effectively aligns the grain structure of the metal and reduces the number of voids. This process allows for tighter control of the weight specs and reduces the amount of hand polishing, leading to a more precise clubhead. The grooves are milled into the face so that they can be manufactured closer to the R&A/USGA limit. A channel behind the hitting area is filled with a thermoplastic urethane to keep the feel just right.

- Weight in the toe places the CG closer to face centre.

- The TPU insert delivers the soft feel better players demand.

- A shorter hosel length helps bring spin down.

- 7-iron: 32 degrees; PW: 44 degrees

Top 5 softest feeling, players irons, low swing speeds

“I can fade or draw it without the ball spinning much. Has a lower launch but a takeoff that lets the ball stay in the sky longer.”

– 4-Handicapper